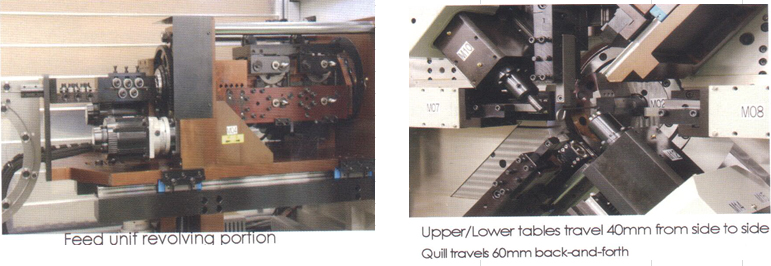

* Feed unit having revolution mechanism newly developed does not need offset.

Center of gravity is at very center of revolution, i.e. only a little bit of moment of inertia results

in hi-speed and smooth wire revolution, and also no vibration even though ultimate hi-speed

* integrated feed unit including quill moves 60mm back-and-forth, and it is easy to make

adjustment of coil diameter, twirl, form parts having long tail and so on.

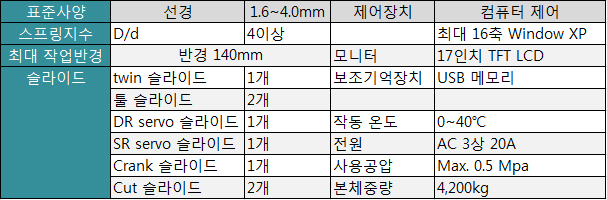

* Main tooling table is divided into 2 parts up and down, i.e. slides arranged on each table move

+/-53mm from side to side. Adjustment for initial tension, making pitch, alignment of grooves

on toolings and such can bo made with program.

* Quill has 140mm in depth and Slide travels 160mm that give enough room for twirling of products

* 4 toolings at max can be mounted on the twin slide that is driven by only one motor

* 2 R servos, one having inner/outer double-revolution, and another having only outer end

single-revolution, are equipped as standard spec. Furthemore, WR servo can be moved frontward

as far as 100mm at max.

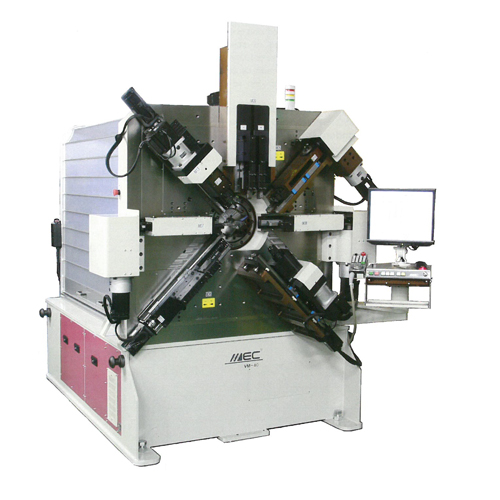

* program display controlled by "MNO" is easy-to-read, i.e. program flow, each axis operation status,

input/output, jump and so on can be grasped by scrolling.

* Easy to make long program and also shorten setup time with multifunction.

* Gauging,Coiling control, Input/Output and such program screen comes on independently.

Motor Sensor System (Standard spec.)

Positioning function is used by applying contact probe to drive servomotor.

It measures free length, outside diameter, leg portion angle in 1/1000mm resolution, and performs

corrective control. It functions as well as capacitance sensor or sontact type seneor.