- Total 8-axis control.

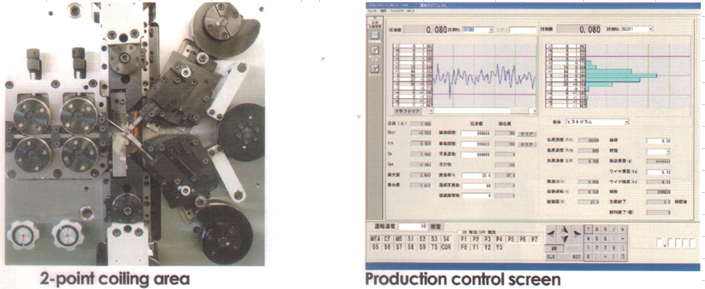

* Switching to/from right wind from/to left wind can be done with program only-3-axis control coiling

point portion.

* There is no need to re-align arbor with cutting cool for cut slide, Wedge pitch slide and arbor that

are equipped on the center slide.

* Switching to Oscillating cut, Straight cut, or Wedge pitch can be done easily by moving eccentric pin.

* For general spring pats like cylindrical springs and conical spring, dimensional data input on to the

pattern program will be converted to produce desired parts accordingly. For variation of conical springs

staight, bowl and such shape can be formed adjusting in multi-step up to 100-step, and desired load can

be achieved .

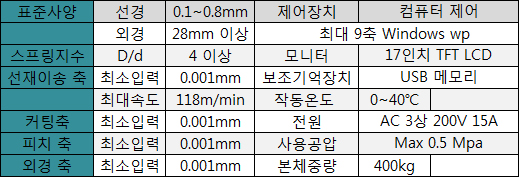

* Program display controlled by "MNO" is easy-to-read, i.e. program flow, each axis operation status

Input/Output, jump and so on can be grasped by scrolling.

* Easier production control with Capacitance gage, Auto correction, and multi functional prodyction control

monitor.

Motor Sensor System (equipped as standard spec.)

Touch sensor is applied to positioning function for cut or pitch axis driving servomotor.

It measures free length, outside diameter and so on in 1/1000mm resolution same as capacitance gage or

contact type gage, and correction control can be processed with graphic display